QUALIDADE

Acolchoado até 100mm

ECONOMIA

Zero desperdícios

entre tampos

PRODUÇÃO

Produção até

30 tampos/min

PRODUTIVIDADE

Ganho efetivo de 20% no fecho de cada colchão

INDÚSTRIA 4.0

Interage em tempo integral com o operador, permitindo-lhe receber informações em tempo real.

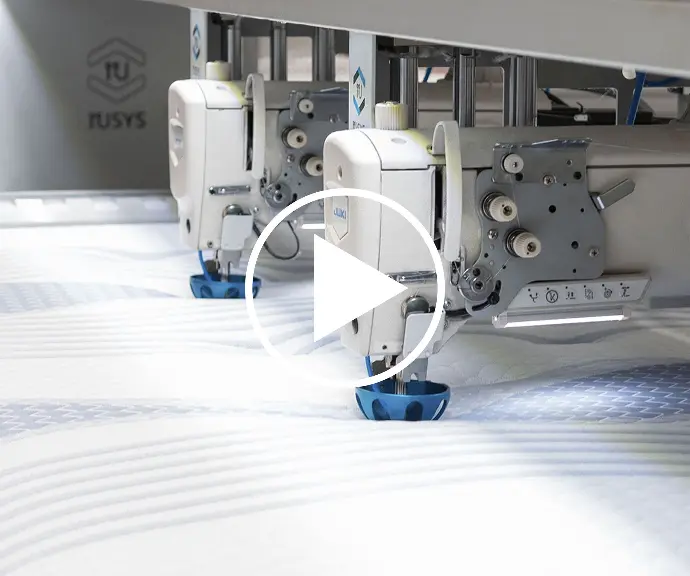

Qualidade & Performance

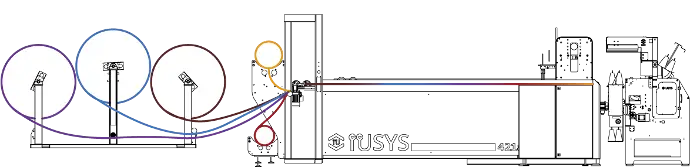

A IUSYS 421a foi concebida para ser a máquina que melhor combina qualidade e desempenho na indústria de acolchoados. Com desempenho eficaz proporcionado por duas cabeças de costura JUKI, a IUSYS 421a costura até 3500 RPM atingindo a marca de 30 tampos acolchoados e costurados por hora. Esta máquina está equipada com recursos únicos capazes de tornar a sua produção não só mais eficiente, mas também mais consistente e eficaz.

Acolchoado sem imperfeições

Para acabar com as pregas, a IUSYS 421a está equipada com um calcador exclusivamente dedicado à obtenção de um resultado final de excelência, com acolchoados livres de pregas e deformações. Esta caraterística confere elevada qualidade e excelência ao seu produto final.

Optimize cada segundo da sua produção

A IUSYS 421a é uma máquina compacta, mesmo em comparação com as máquinas de acolchoar verticais, que une duas actividades essenciais, o corte e o transporte, eliminando não só a necessidade de um operador adicional, mas também permitindo que os tampos sejam facilmente colocadas no colchão e fechadas mais rapidamente.

Área de trabalho | Comprimento = X | Altura= Y: 2400mm x 2800mm

N.º de pontos por minuto:até 3500rpm

Largura do ponto: 1 a 6mm

Velocidade máxima de costura até 21m/min

Offset automático

Cabeça JUKI (Japan) com corte de linha integrado

Servomotor Omron (Japan) com tecnologia EtherCAT

Ajuste de ponto de laçada eletrónico

Detetor de linha superior p/ hardware

Detetor de linha inferior p/ hardware e sotfware

Detetor de canela

Detetor de pontos falsos

Detetor de falta de tecido

Suporte de material: 1 (tecido superior) + 1 (tecido inferior) + 3/4/5/6 (enchimentos)

Sistema de Puxo traseiro para apoio a materiais mais pesados

Antecipação da mudança de material e indicação da posição de corte

Máquina de costura com guia apoiada para união de tecidos

Deteção da falta de tecidos

Posicionamento eletrónico automático dos cortes laterais

Puxo uniforme com rolos de grande diâmetro

Corte lateral com discos de Ø 260mm com subida e descida pneumática

Movimento eletrónico dos cortes laterais

Posicionamento eletrónico dos cortes laterais

Corte transversal com posicionamento elétrico

Sistema de remalhar tampos (4 lados) – ver mais

Kit de extratores laterais

Kit de extração frontal

Rolos em borracha fundida

Empilhador automático de Tampos – ver mais

Controlador

Omron NJ

Portas EtherCAT e EtherNet/IP incorporadas

Capacidade para efetuar múltiplas tarefas

Núcleo de movimento sincronizado

Funções: sequência lógica, motion, CNC, robótica

Ligação às bases de dados e SECS/GEM

Ligação à BD: cliente SQL para servidor SQL da Microsoft, Oracle, IBM DB2, MySQL, Firebird

IPC

Sistema com telemanutenção

Rede de EtherNet/IP, Wifi e Bluetooth incorporada

Software

Software de controle numérico (IUSYS421-Viewer)

Ampliação e redução do desenho

Alteração do ponto

Edição do desenho

Programa IUSYS421 Design (Ficheiro CAD em .dxf)

Desenvolvimento e criação de novos desenhos

Estudos e análises de diferentes padrões

Exportação direta para IUSYS-Viewer

Importação de outros softwares de desenho (AutoCAD e outros possíveis de estudo)

Visualização gráfica do desenho

Programação e modificação de desenhos mediante monitor táctil

Ajuste automático da altura do calcador em função dos materiais

Caracterização da composição da sandwich do acolchoado

Controlo da máquina através de um smartwatch

Dois monitores de visionamento

Servo-Drives, servo-motores, disjuntores, contatores, relês e outros equipamentos elétricos e eletrónicos da Omron, Siemens ou outras grandes marcas equivalentes

Peso aproximado 5000 Kg

Potência máxima | Tensão | Pressão de ar 15kw | 380V + III + T 50/60 Hz | 6 bar