QUALITY

Quilted up to 100mm

ECONOMY

Zero waste

between

tops panel

PRODUCTION

Production up to

30 tops panel/min

PRODUCTIVITY

Effective gain of 20% on the closure of each mattress

INDUSTRY 4.0

It interacts full-time with the operator, allowing them to receive information in real time

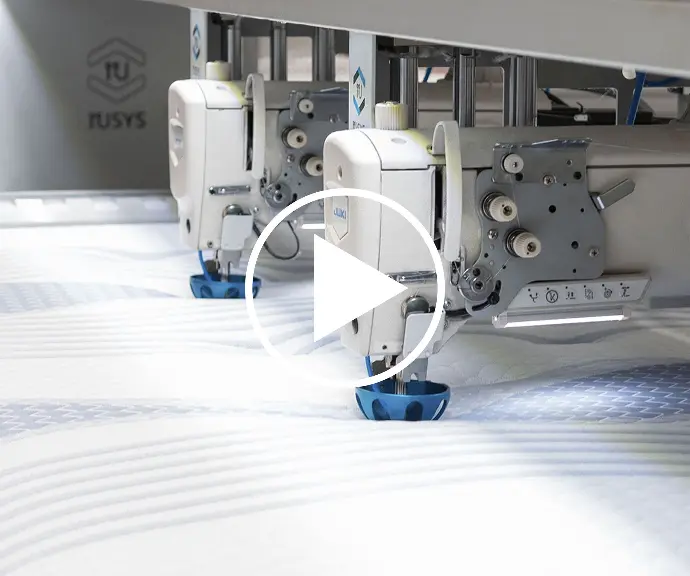

Qualidade & Performance

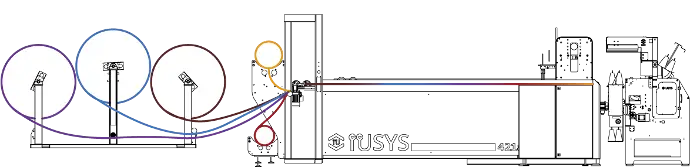

The IUSYS 421a has been designed to be the machine that best combines quality and performance in the quilting industry. With the efficient performance provided by two JUKI sewing heads, the IUSYS 421a sews at up to 3500 RPM, reaching the mark of 30 quilted and sewn tops panel per hour. This machine is equipped with unique features capable of making your production not only more efficient, but also more consistent and effective.

Flawless quilting

To get rid of creases, the IUSYS 421a is equipped with a presser foot exclusively dedicated to achieving an excellent end result, with quilts free of creases and deformations. This feature gives your final product high quality and excellence.

Optimise every second of your production

The IUSYS 421a is a compact machine, even compared to vertical quilting machines, which combines two essential activities, cutting and transport, eliminating not only the need for an additional operator, but also allowing the tops to be easily placed on the mattress and closed more quickly.

Useful work area | Length = X | Width = Y: 2400mm x 2800mm

Number of stitches per minute: to 3500rpm

Stitch width: 1 to 6mm

Maximum sewing speed up to 21m/min

Automatic offset

JUKI (Japan) head with integrated thread cut

Omron servomotor (Japan) with EtherCAT technology

Electronic loop stitch adjustment

Top line detector for hardware

Bottom line detector for hardware and software

Spool line detector

False stitch detector

Lack of fabric detector

Material support: 1 (upper fabric) + 1 (lower fabric) + 3/4/5/6 (fillers)

Rear pull system to support heavier materials

Anticipation of change of material and indication of the cutting position

Sewing machine with supported guide for joining fabrics

Detection of lack of fabric

Automatic electronic positioning of side cuts

Uniform pull with large diameter rollers

Side cut with Ø 260mm discs with pneumatic rise and fall

Electronic movement of side cuts

Electronic positioning of side cuts

Cross section with electrical positioning

Hemming system (4 sides) – see more

Front extraction kit

Side extractors kit

Cast rubber rollers

Automatic Top Stacker – see more

Controller

Omron NJ

Built-in EtherCAT and EtherNet / IP ports

Ability to perform multiple tasks

Synchronized movement core

Functions: logical sequence, motion, CNC, robotics

Connection to databases and SECS / GEM

DB connection: SQL client for Microsoft SQL server, Oracle, IBM DB2, MySQL, Firebird

IPC

System with telemaintenance

Built-in EtherNet / IP, Wifi and Bluetooth network

Software

Numerical control software (IUSYS421-Viewer)

Drawing enlargement and reduction

Point change

Editing the drawing

IUSYS421 Design program (CAD file in .dxf)

Development and creation of new designs

Studies and analyzes of different standards

Direct export to IUSYS-Viewer

Import of other design software (AutoCAD and other possible study)

Graphical drawing visualization

Programming and modification of drawings using a touch monitor

Automatic presser foot height adjustment depending on materials

Characterization of the composition of the quilting sandwich

Control of the machine via a smartwatch

Two display monitors

Servo Drives, Servo Motors, Circuit Breakers, Contactors, Relays and other electrical and electronic equipment from Omron, Siemens or other major equivalent brands

Approximate weight 5000 Kg

Maximum power | Tension | Air pressure 15kw | 380V + III + T 50/60 Hz | 6 bar