IUSYS S4s-A … cuts and hems with the certainty of an increase

effective productivity

High quality

Work connected with your Multi-needle

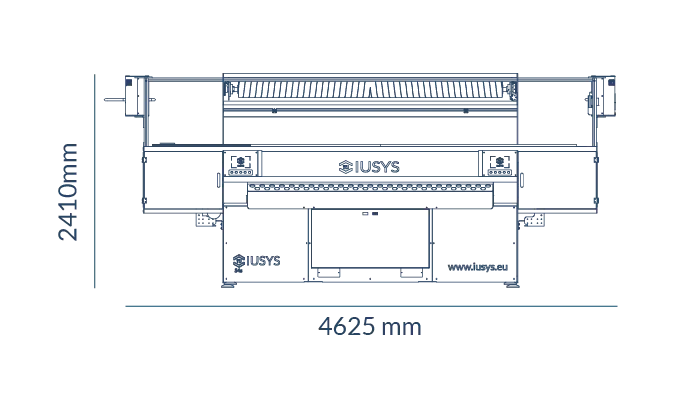

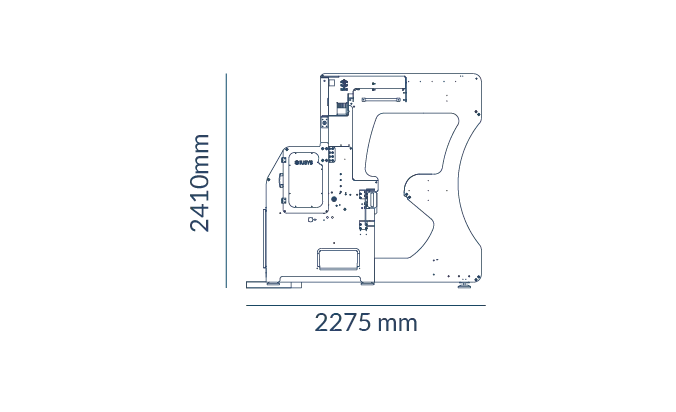

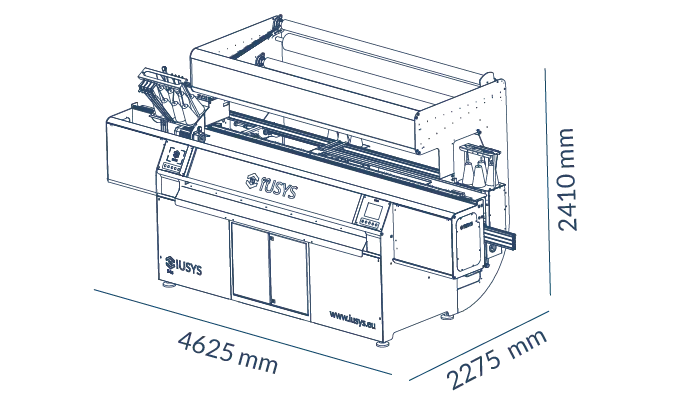

IUSYS S4s-A is designed dimensionally and structurally to be replaced directly by your cutting system, giving you a more complete equipment, with cutting and patching, without the need for additional space.

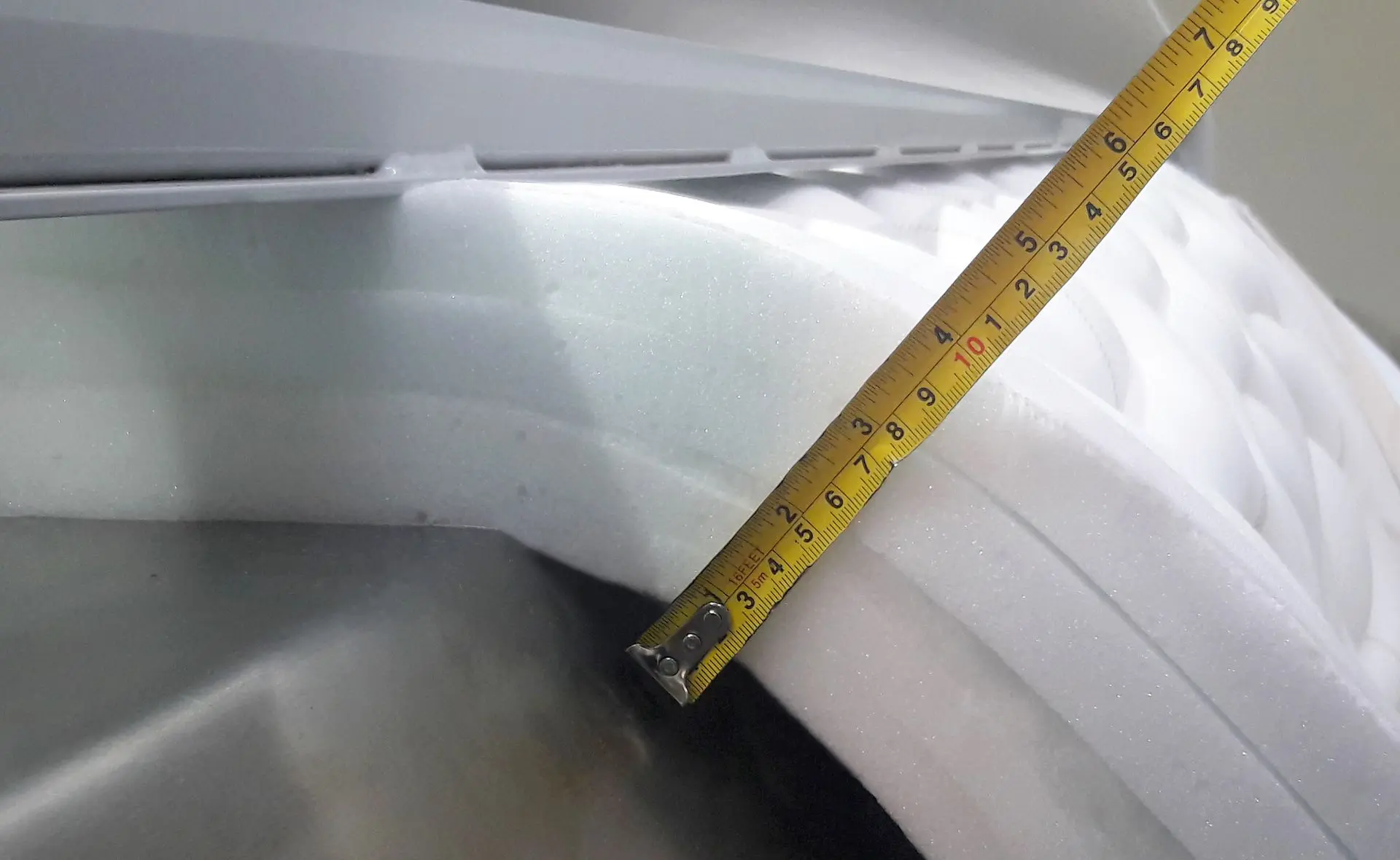

Quilting up to 100mm

With the market’s growing demand for higher and higher mattresses, IUSYS S4s-A is prepared to work up to 100mm high with multiple combinations of materials, such as stretch, latex, viscoelastic, polyester, foam, wool and cotton.

Hems with aligned and precise seams

IUSYS S4s-A is hemmed laterally and transversely, with only 20mm of excess material on the sides, giving perfectly aligned and precise seams to its padding.

High Productivity

Exceed mark of 30 top panels/h

IUSYS S4s-A spreads laterally and transversely, reaching and at often exceeding 30 tops/h, giving perfectly aligned and precise seams to its padding.

Optimize every second of your production

IUSYS S4s-A, when combined with the IUSYS M301a, enhances and optimizes your production by combining two activities that used to be done separately, cutting and patching, thus removing the need for an extra operator and ensuring that the worktop is automatically ready in one go.

Get 20% on the closing of each mattress

The differences between a cut top and a cut and patched top are clear to see. IUSYS S4s-A cuts and sews at the same time, allowing for a 20% efficiency gain by making it easier to position and close each mattress.

Simplified production

Gain 40mm of quilting with each top panel

There is zero waste between padded tops, because with the IUSYS S4s-A the end of one top is the beginning of the other, thus removing the need for a 20mm surplus on either side of the top for the operator to be able to adjust and close the mattress.

Border… For what?

IUSYS S4s-A opens a new window to the creation of totally different and distinctive quilts. The outer edge for the purpose of positioning and closing the mattress is now unnecessary, as when cutting and patching the sizing and positioning of the top is ensured.

Industry 4.0

A safe investment

The IUSYS S4s-A is equipped with Omron, JUKI, Siemens, Igus and Weidmüller, brands that long ago secured their place in the market and which today guarantee spare parts that can be found on the market for 20 years or more, thus guaranteeing an investment that lasts over time.

Don’t depend on an experienced operator for hemming

Hemming a quilt is a task usually carried out by an experienced operator, but not with the IUSYS S4s-A. This machine cuts and quilts at the same time, with the exact dimensions of the top, eliminating the need for manual quilting and allowing you to take advantage of your multi-needle operator.

Chainstitch

Ensure high-speed production

IUSYS S4s-Chainstitch sewing, eliminating the need for permanent lower thread changes and increasing productivity.

Are you interested in knowing more about our equipment?

Fill the form bellow to request a quote, we will get in touch soon.

Complementary information

Useful working area | Length = X | Width = Y: 2400mm x 2400mm

Number of stitches per minute: up to 2500rpm

Stitch Width 1 to 6mm

Maximum sewing speed up to 15m/m – 2-3 top panels per minute (reference value for 200cm x 200cm top panels)

General

3 Juki heads (Japan) chain stitch for 4 rows of sewing and 6 positions with a spacing between them of 6.35mm

Presser foot with synchronized needle movement and up to 20 mm height of the base

Automatic needle on top positioning

Side Seams

2 side sewing heads

2 260mm cutting discs (side heads)

2 Pneumatic disc lifting systems

Fine tuning system for adjustment between cutting and sewing

Cross seam

1 cross sewing head

End sewing automatic thread cutting system

1 130mm cutting disc

Polychrome touch screen

Speed control

Stitch length and speed adjustment

Cutting measurement by encoder or photocell

Automatic / Semi-Automatic / Manual Selection

Allows you to work a quilt up to 100mm in height

Electronic side disk adjustment systems

Multi-needle machine connection system

Roll unwinding system up to 1m of Diam

Encoder counting system 150mm to 9999mm

Roll counting system up to 99m

Bag waste extraction system

Automatic top stacker – see more

Approximate weight 5000 Kg

Maximum power 4.5kW

Voltage 380V + III + T 50/60 Hz

Air pressure 6 bar