IUSYS 421a

IUSYS 421a

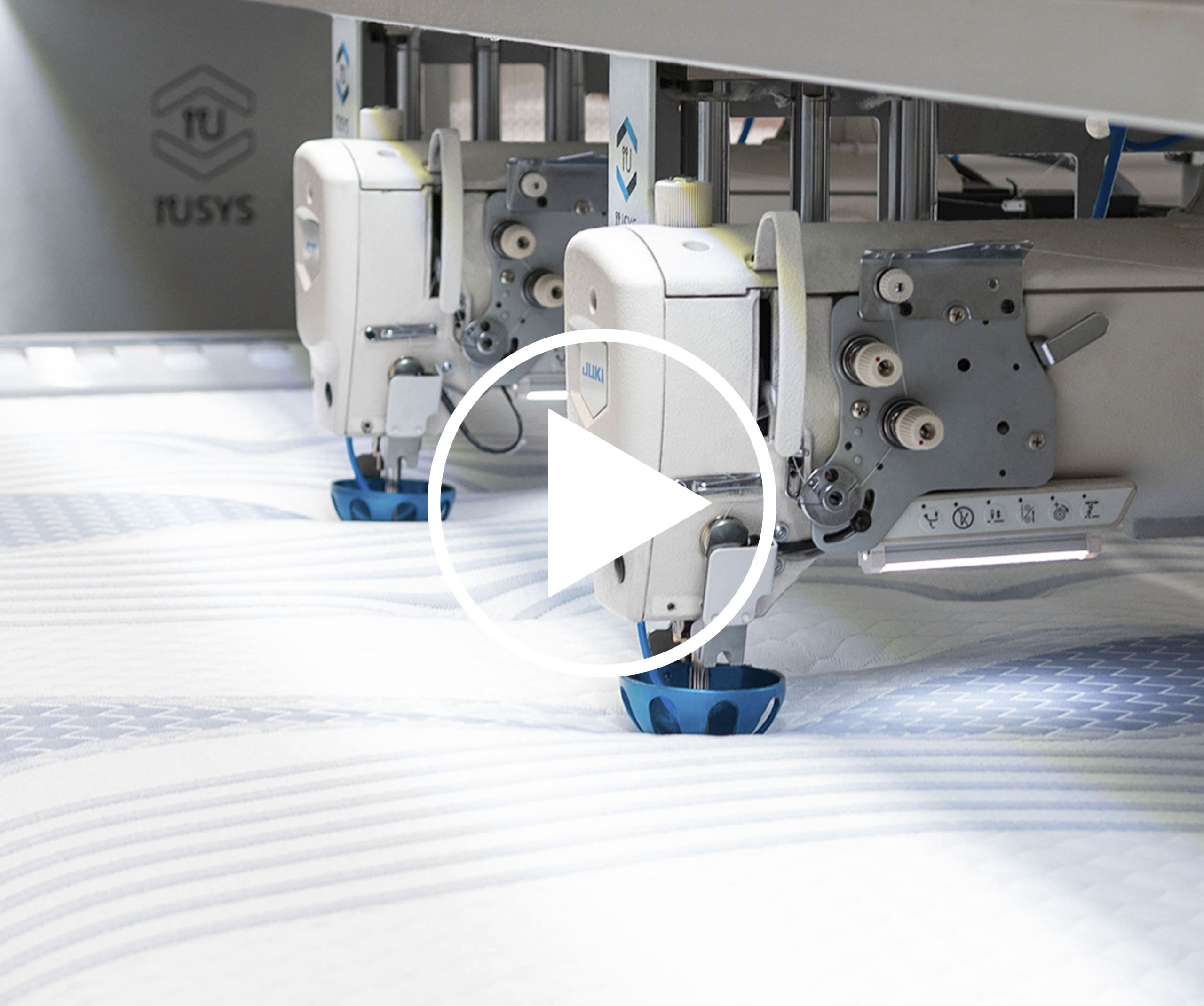

Mattress Quilting Machine

IUSYS 421a …destroys the myth and proves that it is possible to combine

quality and performance

High Productivity

Ability to surpass the mark of 30 top panels/h, with two high performance JUKI heads capable of reaching 3500RPM.

Simplified production

IUSYS 421a cuts and hems to size, making it unnecessary to use an edge to position and close the top panel.

Industry 4.0

Integrated in the current industrial revolution, IUSYS 421a interacts full time with the operator, allowing him to receive information in real time, anticipate actions and increase his productive capability.

High quality

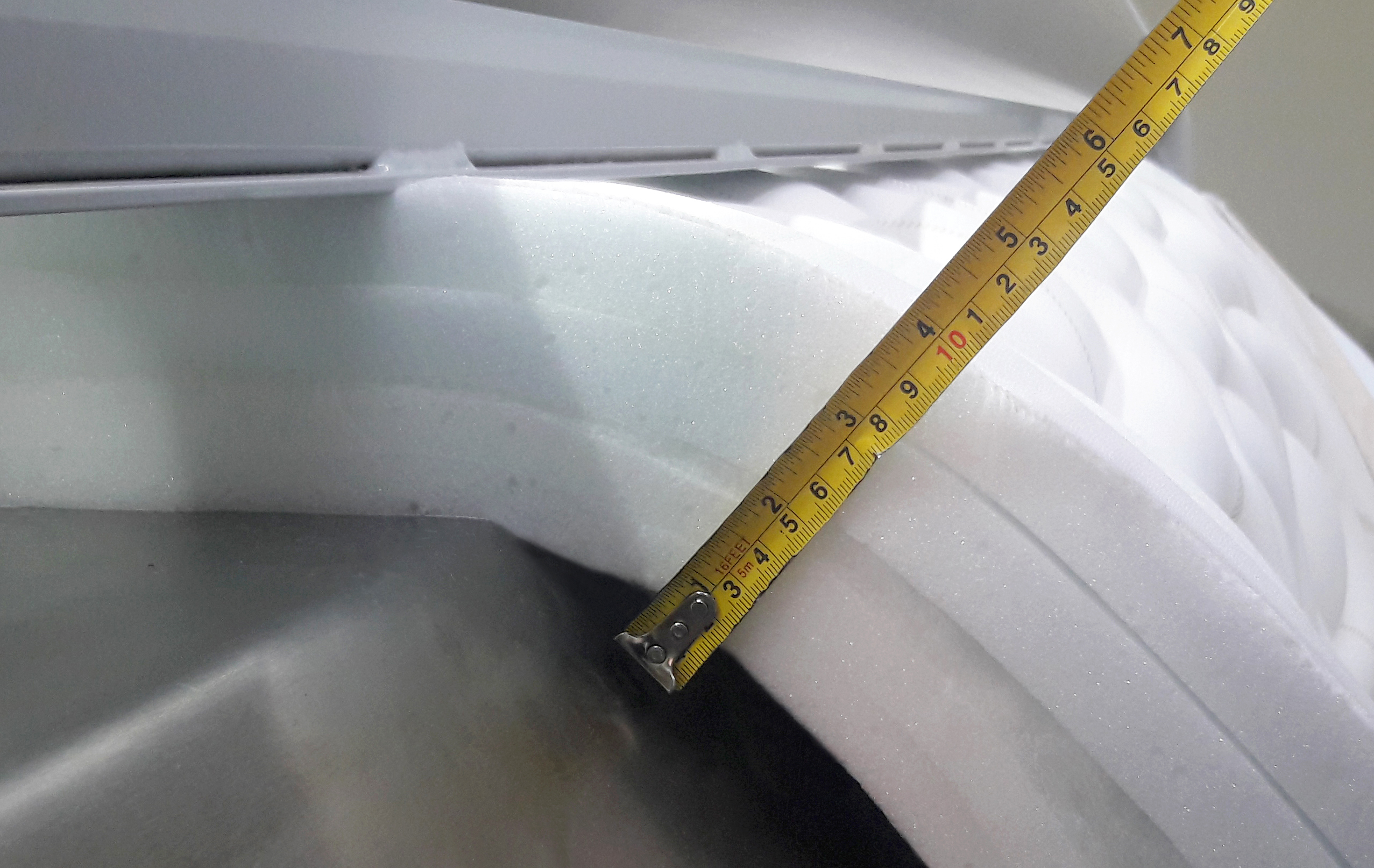

Quilt up to 100mm

With the market’s growing demand for ever higher mattresses, IUSYS 421a is prepared to work quilts up to 100mm in height with multiple combinations of materials, such as: stretch, latex, viscoelastic, polyester, foam, wool and cotton.

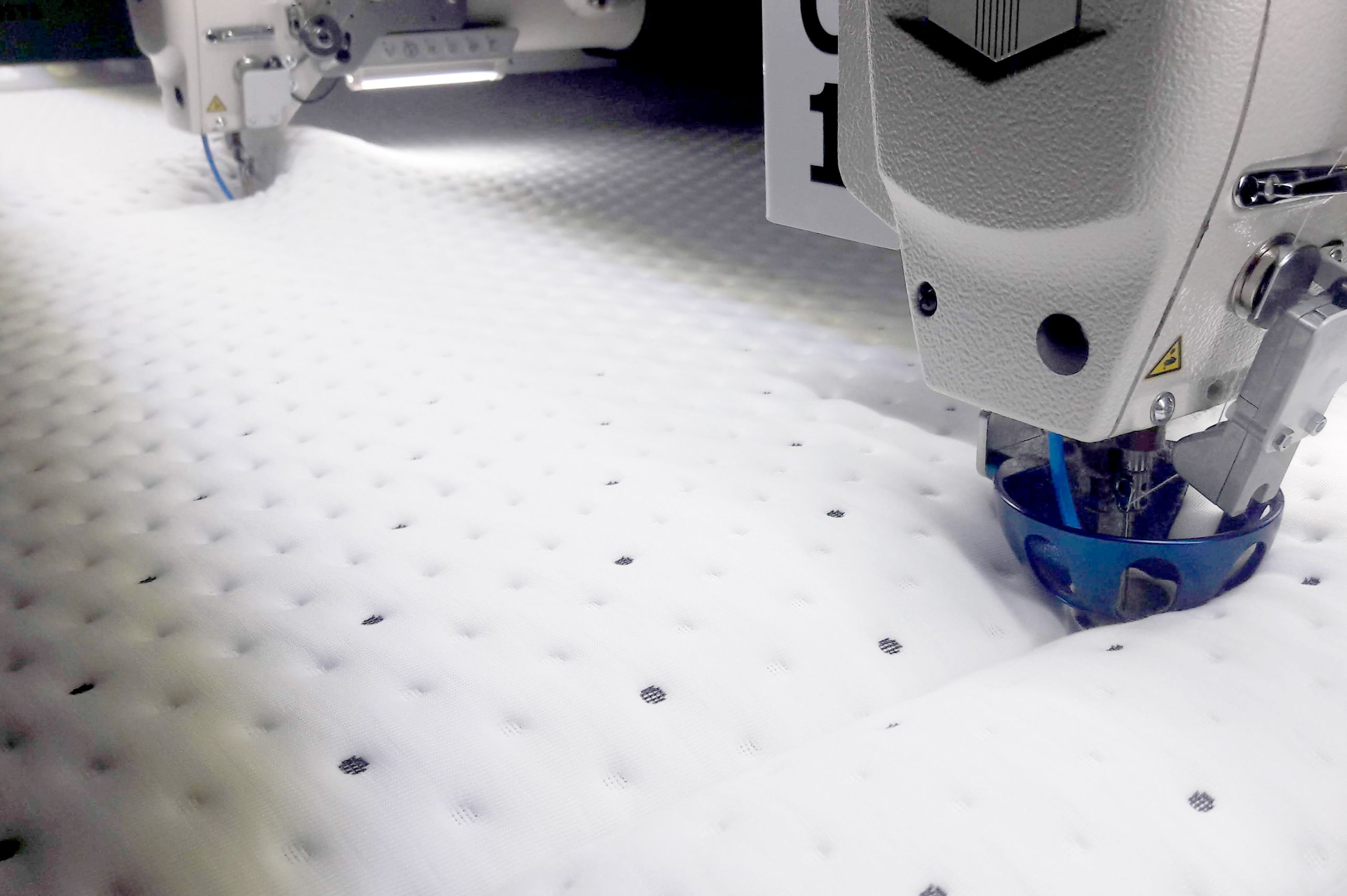

Pleats… Never again.

In order to put an end to the ill-fated pleats, IUSYS 421a is equipped with a presser foot exclusively dedicated to obtaining a final result of excellence, with quilts free from pleats and deformations.

A line is a line

On IUSYS 421a when drawing a line, the end result on the quilting is a line and not a curved line. Regarding the stretching and shrinking of materials, the IUSYS 421a uses the least possible tension and stretching, ensuring that the design designed is the quilting achieved.

High Productivity

Exceed mark of 30 top panels/h

Always favoring an increase in production capability, IUSYS 421a reaches and sometimes exceeds the mark of 30 top panels/h. The entire process is designed to minimize equipment downtime, collecting and anticipating data for the operator, and also using two JUKI heads capable of reaching 3500RPM.

Optimize every second of your production

IUSYS 421a is designed to enhance and optimize your production. This machine joins two activities that used to be done separately, cutting and hemming, thus removing the need for an extra operator, while allowing the top panels to be easily positioned on the mattress and closed more quickly.

Industry 4.0

Extract maximum profitability from all your operators

IUSYS 421a with its ergonomics privileges the ability to keep the operator motivated, by providing information in real time that allows him to anticipate tasks and perform them while the machine is running, enabling continuous work. The anticipation of routine activities makes them less stressful and fatiguing, providing the operator with greater comfort and safety for efficient performance.

Don’t depend on an experienced operator

IUSYS 421a is designed to operate only under two commands, “Yes/No”. Allowing less experienced operators to achieve the same productivity as a more experienced operator.

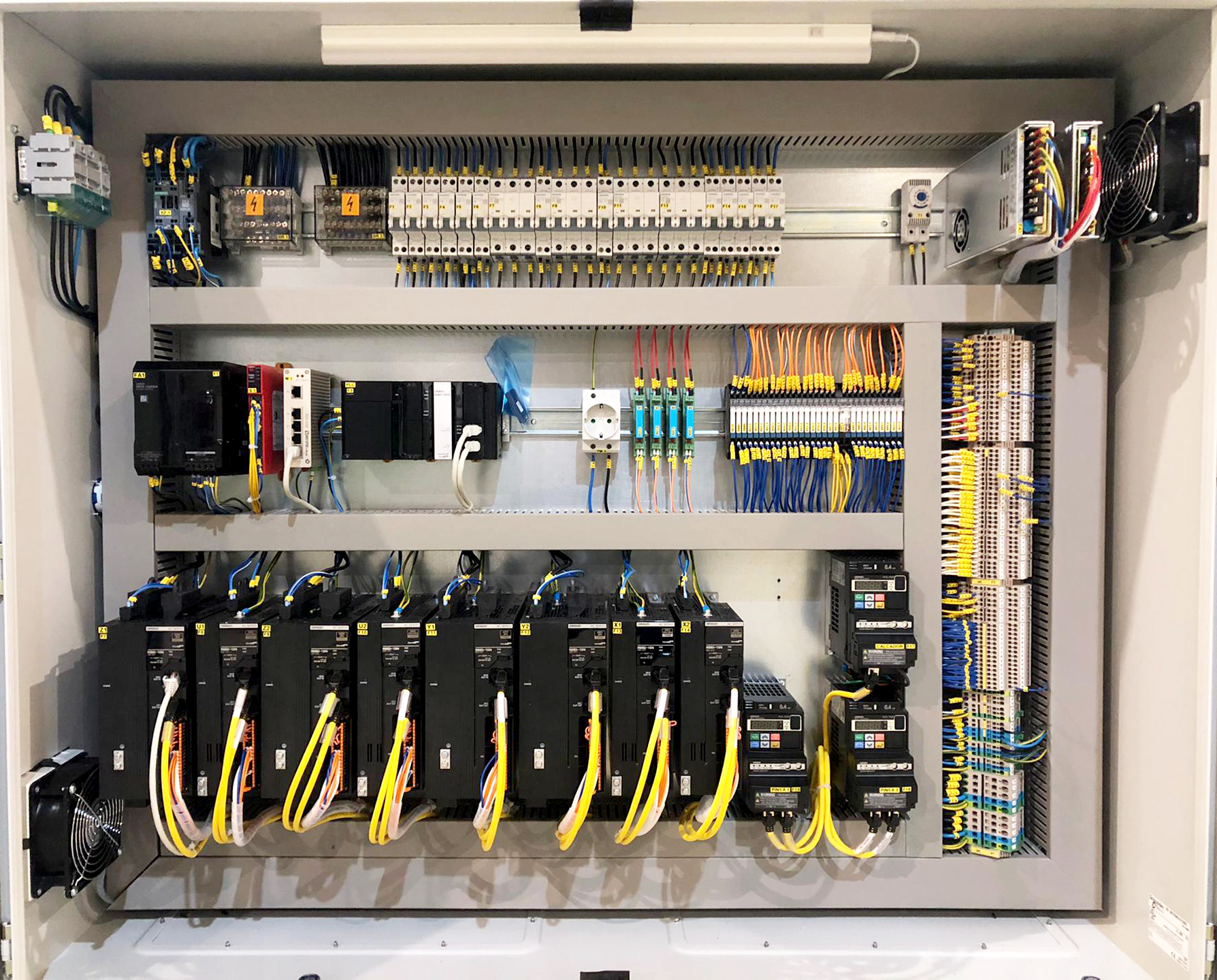

A safe investment

The IUSYS 421a is equipped with Omron, JUKI, Siemens, Igus and Weidmüller, brands that have long secured their place on the market and that today guarantee replacement parts that can be found on the market for 20 years or more, thus guaranteeing an investment that endures over time.

Lockstitch

Quilt with high quality and resistant seams

IUSYS 421a sews in a fixed point (Lockstitch), ensuring greater quality and resistance, which combined with two high performance JUKI heads, gives your quilting a superior quality finish.

Simplified production

Border… For what?

IUSYS 421a opens a new window to the creation of fully differentiated and distinct quilts. The outer edge for the purpose of positioning and closing the mattress is now unnecessary, as the dimensioning and positioning are ensured in the cut and hemming performed.

Are you interested in knowing more about our equipment?

Fill the form bellow to request a quote, we will get in touch soon.